HOW IT WORKS: PRESSURE WASHERS

For a long time, I used a pressure washer without ever trying to understand what goes into making it tick. Honestly, do we even need to know how a pressure washer works to use it? Well, no you don’t need to understand the mechanism of pressure washing but having this knowledge will help in troubleshooting simple problems at home. Spark plug issues, drop in pressure, sudden loss of water flow and similar issues are difficult to diagnose if you have no idea about the workings of a pressure washer.

WORKING PRINCIPAL - PASCALS LAW.

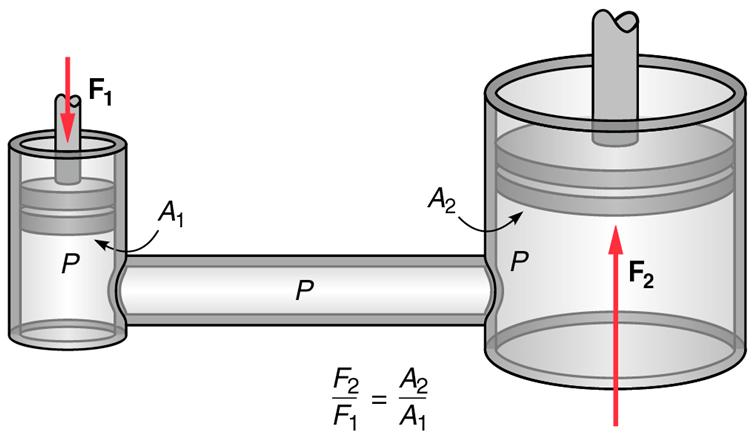

A Pressure washer works primarily on the basis of Pascal’s law, which states that “when pressure is applied at any point in a fluid stored in an enclosed container, the pressure is distributed equally in all directions and to all points of the fluid.” This law is also the root for all fluid dynamics (the term used to describe anything related with fluids in motion, which is what happens in a pressure washer).

When a fluid is compacted in a closed container and pressure is applied at any point, the pressure travels throughout the fluid and is felt equally by every single molecule. Naturally, when water is compressed like this, it will exert an outward pressure on the container holding it. Now assuming that a small opening is made on one side, it allows water to release some of the pressure by flowing out of this orifice at a high compression rate. Theoretically, pressure exerted on the orifice is inversely proportional to the diameter of the hole. Practically, smaller this hole, greater is the pressure with which water escapes.

PRESSURE WASHERS - HOW DO THEY WORK?

A pressure washer consists of basically three parts—the pump, source of water and a high pressure nozzle. Controlling all these components is a toggle switch that allows you to release water or hold it within the tank.

Now, the engine or motor used to power the washer can either be electric or gasoline, as you already know. Regardless of its source of power, the working principle remains the same. The pump is run by a piston and cylinder set, which is driven by a pull chord that draws momentum from the engine. In fact, it has the same working principle of a piston engine. The crankshaft in the crankcase is connected to a set of plungers in the pump. These plungers have the same function as plungers in a syringe—to suck and eject water. The plunger works in connection with a cam. Each plunger is instrumental in sucking water from a temporary reservoir that momentarily stores water from the source and holds it until it is used up and makes space for new water to flow in. When the plunger moves up, the water is drawn into the containing cylinder through an input check valve and when the plunger moves down, the water is forced out through an output check valve into a un-loader. The un-loader is connected to a trigger type switch and pressing it releases the pressurized water out of a long narrow nozzle, thus producing pressurized water.

When the trigger is compressed, water flows out and when it is released, the water flow stops. When you release the trigger, a spring valve detects the stopped water flow and allows it to go return to the reservoir or inlet pipe. This keeps circulating until the trigger is pulled. The spring valve mechanism allows the motor to run even when the flow is stopped. During the circulation if the temperature of water increases beyond a particular level, a release valve flushes the hot water, making space for cooler water to flow in.

TIPS AND PRECAUTIONS

Ok so now that you know how a pressure washer works, here are a few tips and precautions that you will appreciate even more. Well, most of these are written on the product or its packaging but who ever reads them!

Care should be taken to use the right fuel for the pump

Regular oiling of the pump is required to ensure that its piston and other moving components experience minimum heating.

Always flush air from the inlet pipe before starting it otherwise it can damage the valves causing leakage or drop in pressure.

The carburetor should be cleaned regularly for obstructions and should be replaced as and when necessary.

Use a mild detergent to clean the pressure washer and its components.

Original article posted by Pressure Washer Critics.